Wilson Creates 3D-Printed Airless Basketball That Doesn’t Deflate

By Mikelle Leow, 21 Feb 2023

Being the maker of the official basketball of the National Basketball Association (NBA), Wilson Sporting Goods has found itself jumping through hoops to top its design game. Now, the brand has taken the leap by sucking the air out of the basketball, making it resilient against hard-hitting impact across the court.

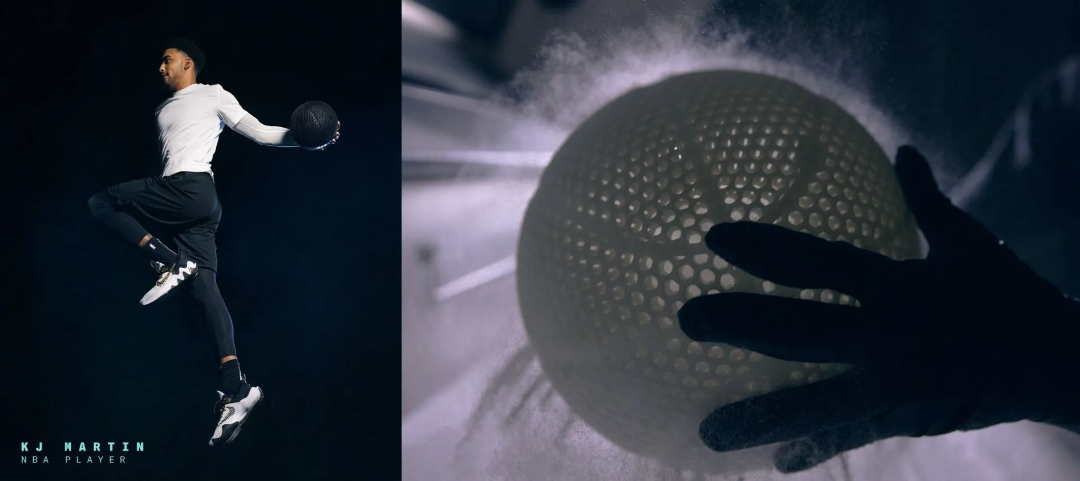

The ‘3D Airless Prototype Basketball’, touted as a world-first, made its debut on the first round of the AT&T Slam Dunk Contest on Saturday night, with Houston Rockets player Kenyon Martin Jr. making a slam dunk on his third attempt with the innovation.

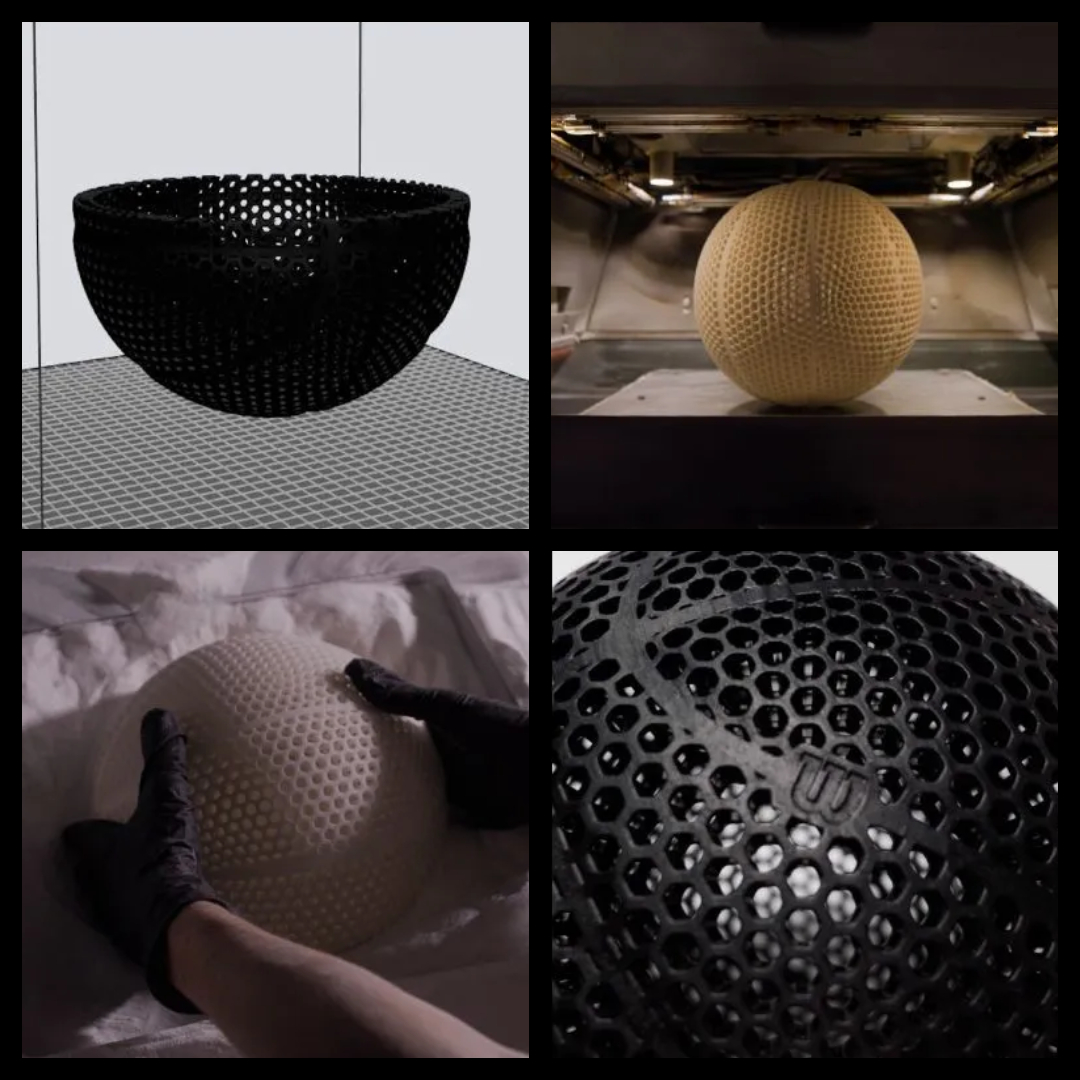

Wilson “identified a part of the ball everyone took for granted—and completely removed it from the equation,” the company explains on its website. The ball, 3D-printed in one piece, is designed to be fully playable, and its current version is said to be nearly on par with the standard basketball in terms of weight, size, and rebound.

Where it differs, aside from appearance, is that it doesn’t need to be inflated. The ball gets its superpower from its lattice of eight panel-like ‘lobes’. The prototype was created by Wilson Labs, with computational design by General Lattice, additive manufacturing by EOS, and color and finishing by DyeMansion.

The meshed ball won’t replace the official NBA basketball, however. Wilson details that, more specifically, the design is a tried-and-true symbol of its commitment to innovation in sports. “This is only a dot on the development path,” describes Bob Thurman, the brand’s VP of innovation.

In fact, the company emphasizes that the prototype will require some tweaking before it can be used in courts around the world.

“But we’re thrilled by the possibilities this ball represents,” Wilson comments, elaborating that the already playable iteration spells possibilities for future products, even for those used for other sports. “This is an innovation made to push boundaries and open imaginations.”

[via All3DP and 3D Printing Media Network, images via Wilson]